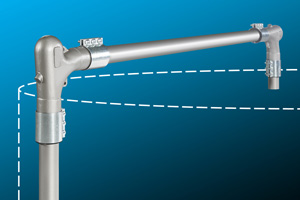

Deflection Elbow Kits for Silo Top Fill Lines

Smart Elbow® deflection elbow kits for socket style (shown) and flanged pneumatic conveying lines allow direct replacement of failed sweep elbows and related piping/tubing, with all preparation done safely at ground level.BETHLEHEM, PA—New Smart Elbow® Deflection Elbow Kits from HammerTek® Corp allow direct replacement of silo top elbows and piping/tubing subject to abrasive wear, with all preparation done safely at ground level. Each kit contains all components required to replace failing elbows, including two Smart Elbow® deflection elbows and all necessary piping/tubing, connectors and gaskets. All can be assembled on the plant floor prior to silo top installation, reducing personnel hazards associated with maintenance at high …- HammerTek is the only one-product company that offers specialty elbows for pneumatic conveying systems. Yes, our SMART-ELBOW® Deflection Elbows are available in cast iron, carbon steel, aluminum, stainless steel and other alloys; at 90- and 45-degree angles, and with either flanges or socket-weld ends, but it doesn’t change the fact that elbows are all we do! And it’s been that way since HammerTek’s beginnings back in the early 1980’s. Over the years, we’ve seen ads …

- In conventional pneumatic conveying systems, materials impact the elbow wall at high speed to change direction. As a result, abrasive materials can wear through the elbow wall, fragile materials can break apart, and heat-sensitive materials can build-up and clog the elbow. When plastic pellets impact and heat the elbow wall, they often melt, forming streamers, angel hair and snakeskins. A simple maintenance step to prevent these problems is to replace conventional sweep elbows, ceramic-backed elbows …

- Pneumatic conveying: you love it. No other conveying option comes close to moving large volumes of materials over long distances, completely and quickly. Whether in dense phase or dilute phase, pneumatic conveying tends to blow most other options away, both literally and figuratively. So what’s the downside? Well, unless you have the rare system that runs in a straight line from intake to outlet, there will be a bend–usually multiple bends, in the convey line. …

Comparison of Elbows for Pneumatic Conveying of Plastics

Below is a chart comparing various types of elbow designs and how they perform against specific elbow-related problems in a pneumatic conveying system. Each elbow is rated by various categories including degradation, noise levels, downtime and costs. They can range on a scale of excellent to poor in relation to how that specific elbow performs in each situation. Performance Comparison by Elbow Type When Conveying Plastics* Excellent Good Fair Poor ELBOW-RELATED FACTORS ELBOW TYPES …

Below is a chart comparing various types of elbow designs and how they perform against specific elbow-related problems in a pneumatic conveying system. Each elbow is rated by various categories including degradation, noise levels, downtime and costs. They can range on a scale of excellent to poor in relation to how that specific elbow performs in each situation. Performance Comparison by Elbow Type When Conveying Plastics* Excellent Good Fair Poor ELBOW-RELATED FACTORS ELBOW TYPES …- If two products look to be nearly the same, either in appearance or in function, most people will select the less costly option. “That other product was too expensive,” is a common refrain among decision makers, post-purchase. Selecting the less costly option can seem beneficial at the time, but when purchasing plant equipment, such as pneumatic elbows, less upfront cost can prove costly in the future. Your conveying elbows should not be thought of as …

Reduce Turbulence in your Conveying Line and Improve your System’s Performance

Generally, in a conveying system, the air in the center of the pipe moves faster than the air traveling closer to the pipe walls. This even, transitional flow helps to create an insulation around the wall of the pipe, reducing impact, noise and the generation of heat. Turbulence in the piping disrupts the flow and weakens the insulation created by the slower moving air; therefore, maintaining a smooth transitional flow helps to control heat and …- For many plants, efficiency is key for having a profitable facility and system that runs smoothly. A lot of times when shipments come in, the pace of getting material off the truck or rail car can be slow. This is commonly due to waiting for the system to take all the material and transferring it to the convey line. Plant Managers are always trying to find ways to quicken their conveying process and make things …

Eliminate Fines, Streamers, Angel Hair and Snake Skins When Conveying Plastic Pellets

In a pneumatic conveying system, fines, streamers, snake skins and angel hair are common issues associated with the transferring of plastic pellets. This damage to conveyed material typically creates problems within the system. When heat-sensitive pellets enter the conveying system, they begin moving at a rapid rate. As they approach a turn in the conveying line, they will slide against the wall of an elbow causing frictional heat, which is the primary contributor to the …PBE-News: Ask an Expert – Preventing Erosion in Pneumatic Conveying Lines

Powder and Bulk Engineering’s PBE-News’ Ask an Expert feature addressed options to mitigate erosion in pneumatic conveying lines. Ray Cocco from Particulate Solid Research Inc. mentions various methods of reducing erosion. One suggested method is replacing the type of elbow used in the system. The proper elbow could minimize impact and reduce, or eliminate, the erosion within a bend. Preventing elbow erosion has been a top priority for many industries as elbow blow-outs can be …